hilion Main menu

All Menu

Roll-to-roll direct coating device

In a roll-to-roll direct coating device, several rolls rotate adjacently and a hopper is used to inject powder between the first and second rolls. The powder is formed into a film and moves along the surface of the roll to the next adjacent roll, becoming thinner and denser. and is finally bonded to the substrate foil between the last two rolls rotating in opposite directions at the same speed. Hilion offers a variety of devices to suit any purpose.

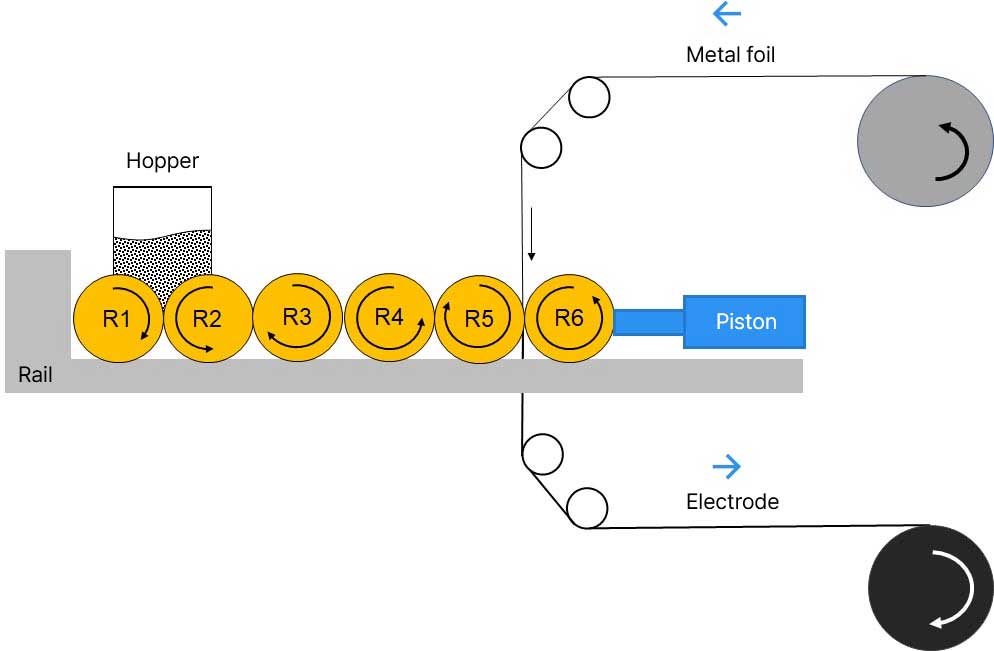

6-roll single-side coating system

This is a system that allows single-sided coating with six heating rolls arranged on a rail. Thin and dense films can be obtained through multi-stage rolling. A motor is used to control the rotation speed of the roll, and induction heating is used to control the temperature of the roll. In addition, force is applied using a piston to adhere to the substrate foil at a constant pressure.

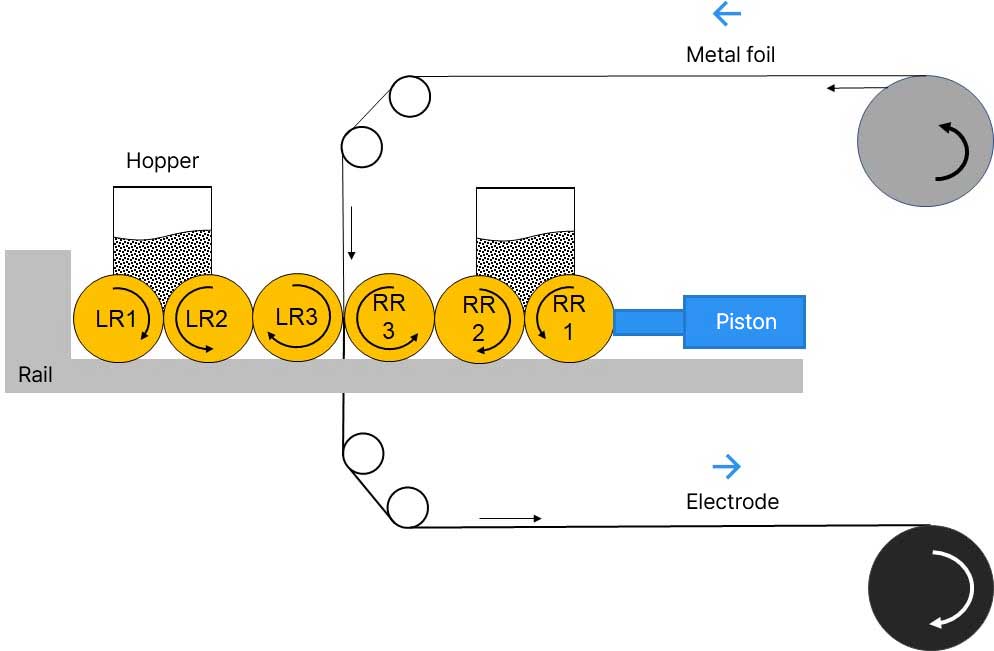

6-roll double-side coating system

This is a system that allows double-sided coating with six heating rolls arranged on a rail. A motor is used to control the rotation speed of the roll, and induction heating is used to control the temperature of the roll. In addition, force is applied using a piston to adhere to the substrate foil at a constant pressure.